As companies grow and evolve, their needs change—and that’s proven true for one longtime ControlByWeb™ customer. D-J Engineering serves the aerospace industries, providing high-caliber engineering and manufacturing for even the most complex projects at low production runs. They’ve grown to an organization of 300+ employees spread across three campuses; two in Kansas and one in Newfoundland. With that many buildings, HVAC and other I/O automation becomes increasingly complex—and increasingly necessary.

In charge of industrial control and ever-expanding special projects at D-J Engineering is Technical Analyst Tarka Ellips. Before she started, the company was using Ignition SCADA software to monitor temperatures across a variety of machines. Some ControlByWeb devices were also being powered by their own on-board logic. Tarka stepped up the company’s use of Ignition and found ways to implement our controllers and sensors within the SCADA to extend programmability.

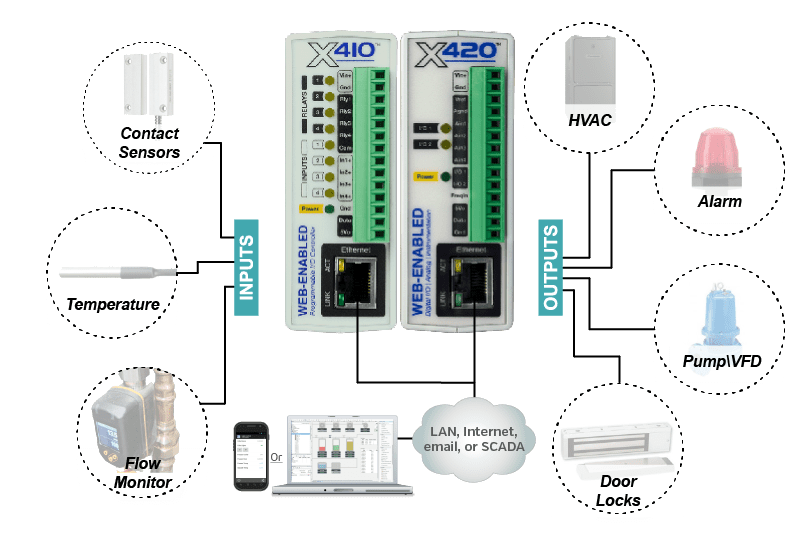

Currently, Tarka is using ControlByWeb’s X-400™, X-405™, X-410™, and X-420™ units across applications that include controlling AC units, monitoring temperature of a mylar room (archived engineering prints), and monitoring the operating temperature and inflow and outflow of water jets. There are plans to expand D-J Engineering’s use of our controllers and sensors—something Tarka’s been discussing with ControlByWeb Sales Engineer (and all-around I/O expert) Eric Bennett.

“Every time I come across some harebrained idea that might work for these modules, I run it by Eric and he’s like, ‘yeah, use this module.'” ‐ Tarka

Common I/O Problems

Compatibility Headaches

Some devices don’t work as well outside of their own ecosystem.

Too Expensive or Unreliable

Low cost monitoring and control is often unreliable, costing more to maintain.

Limited Use-Cases

Devices that are purpose-built often have narrow applications.

ControlByWeb™ Solutions

Seamless Integration

Our modules work just as well in other software as they do using on-board logic.

Low Cost & Reliable

Affordability without sacrificing quality, justifying monitoring in more places.

Limitless Potential

Monitor and control anything, anywhere‐your only limit is your imagination.

Current Applications

Buddy Willis, director of technical services at D-J Engineering, is no stranger to our products. “I think we’ve been using ControlByWeb for possibly 7, maybe even 8 years. Initially what I was looking for when we started going down this route was something that could be PoE-powered and able to record [data]. And then Tarka expanded on that.” Originally, Buddy had been using an X‐600™ as a centralized device to operate outside of a SCADA.

One strength of ControlByWeb’s products is the flexibility they offer to either be powered through our web interface or plug-and-play with other software. D-J Engineering uses a combination of the ControlByWeb device’s on-board logic and a MODBUS map for I/O that sends data to Ignition to be acted upon. Other devices that D-J Engineering use have had their share of issues integrating.

“Some of these devices that aren’t [ControlByWeb] devices have issues connecting with [Ignition], but your devices are green all across the board.” ‐ Tarka

This ease‐of‐integration and optional on-board logic has led the company to incorporate our devices in various applications across their campuses.

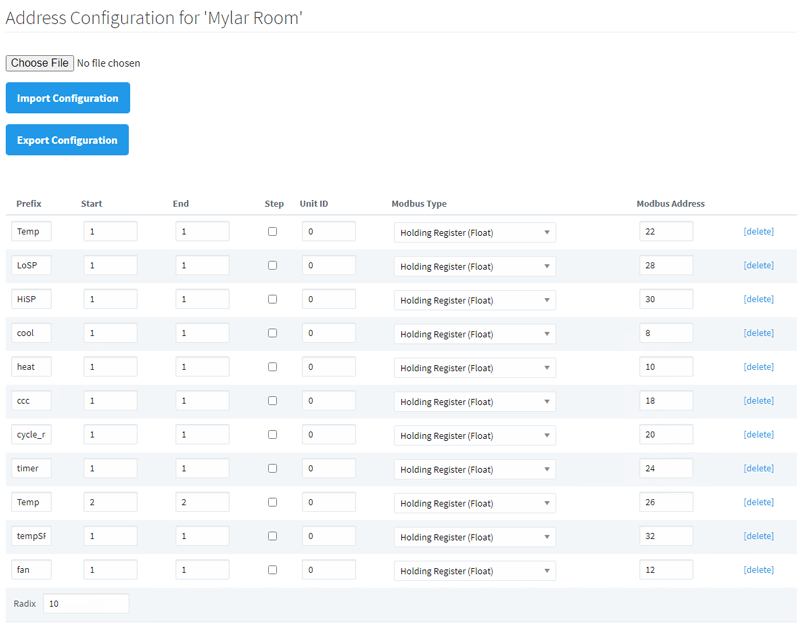

A view within Ignition logging temperature values for the mylar room.

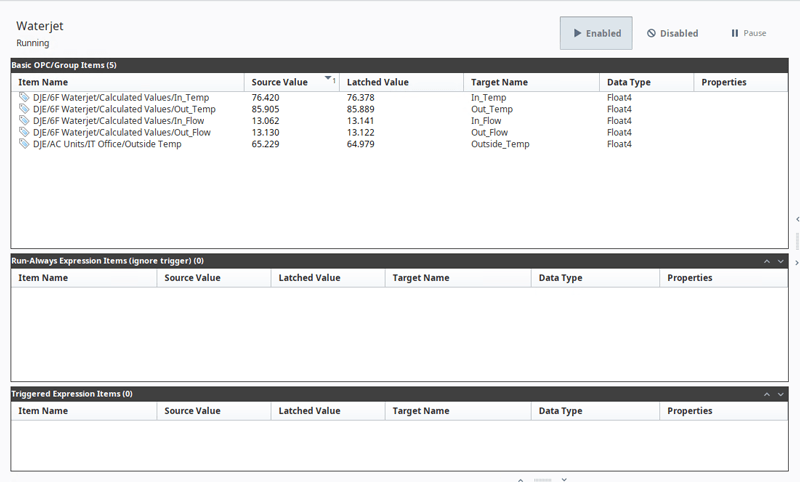

A view within Ignition where a transaction group has been set up to log temperature values and flow rates from the water jet to the database.

FREE DATA ACQUISITION CONSULTATION

HVAC Control

D-J Engineering uses our X‐410 to control several AC units, and the end goal is to use ControlByWeb devices to control all 100+ units across their campuses. The X-410’s on-board logic controls the unit while data from the output relays and connected temperature sensors is shared with Ignition which tracks and controls cooling, heating, and fan status, and tracks temperature via readout. An onboard timer and logic prevents fast cycling the AC unit. Through a script and logic in the task functions section of Ignition, D-J Engineering is able to monitor the timer, reset cooling cycles, and make adjustments to the fan and temperature setpoints.

Another priority is the mylar room. D‐J Engineering keeps engineering plans printed on mylar, a durable polyester film, in a temperature-controlled room. It’s imperative that the environment is kept within a specified temperature range to maintain the integrity of the sheets over years. There are two sensors monitoring the temperature placed in opposite corners of the room. The setup is similar to the AC units with additional logging and tags that are sent to a Microsoft SQL Server to be made available for QA review via a proprietary in-house developed software.

The two sensors generate temperature readings and, if the average of the two goes above the temperature threshold, a notice is sent out which is generated from an Ignition alarm pipeline. All the while, our modules are internally logging the temperature data‐a nice redundancy in case of a lost network connection.

Operations and Machinery

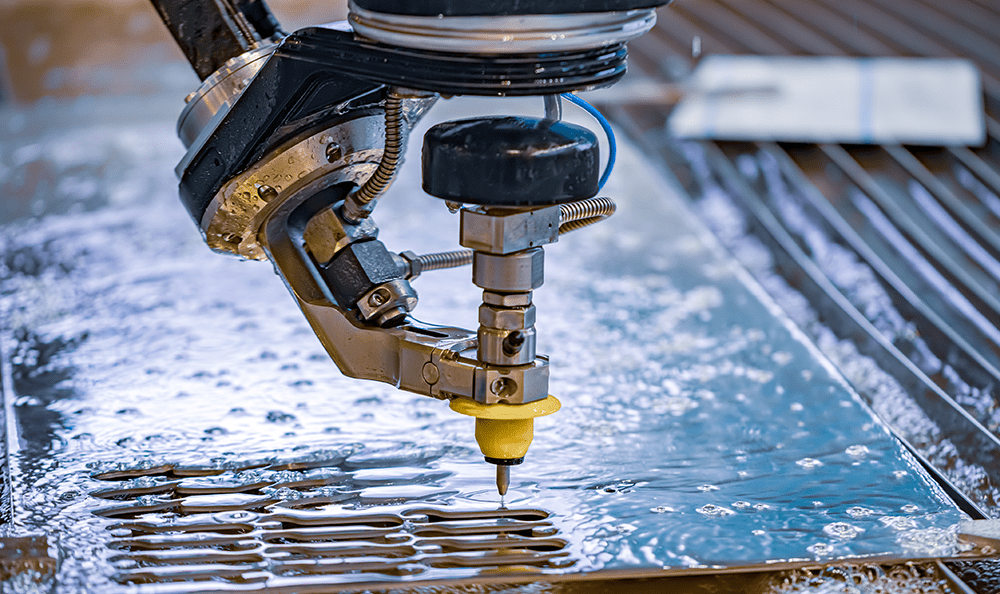

Beyond design and engineering, D‐J Engineering utilizes equipment for metal forming, machining, welding, and more. Their CNC mills are capable of producing parts up to 60′ in length!

The company experienced an issue where their water jet cutting machine’s cooling system was constantly running. It already had a temperature monitor, but there was no shutoff control or way to log data from it. Tarka installed temperature sensors and IFM flow meters which send a 4‐20 mA signal to a ControlByWeb module. This allows her to see if the cooling system is running while also giving temperature values. Additionally, Tarka thought outside the box—literally—by monitoring outside temperature to “see if I can‐t correlate some data between outside temperature and what the cooling system’s running at.”

Like their HVAC applications, all this data surrounding the water jet is logged in Ignition to an SQL Database. The company is now able to produce reports that show cost savings for the machinery.

Future Applications

Impressed by ControlByWeb’s support, device reliability, and flexibility, D‐J Engineering has plans to incorporate our modules and sensors in more applications down the road. There’s the plan to control every AC unit across their campuses. They’re in the process of adding additional ultrasonic sensors to monitor tank and coolant levels of the water jet. Door sensors have already been added at one location, to send alerts for when a freezer door has been accidentally left open, and implementing them at other facilities is on the horizon as well.

There’s also talk of utilizing ControlByWeb devices for lighting, garage doors, and airflow. It all comes down to the quality of our products and the support team that stand behind them.

“Through ControlByWeb support, I was able to get them set up. I pretty much have everything covered … the support is just so wonderful.” ‐ Tarka

Why Choose ControlByWeb

- Right Features, Right Price.

Our devices offered what D-J Engineering needed, including Power Over Ethernet, at a great value. - Really, really reliable.

Buddy couldn’t recall any issues with our devices, and the company has been holding on to older units they’re replacing since they never showed any replicable issues. - Plays Well With Others.

ControlByWeb’s products work just as well with other software as they do with their own on-board logic. Tarka uses our platform and also sends sensor data to Ignition. - Flexible for Any Application.

What started with a single I/O controller has expanded into multiple ControlByWeb devices being integrated across the company—with more applications on the horizon. - An Outstanding Sales and Support Team.

D‐J Engineering continues to be impressed by our knowledgeable team members, who are a quick call away to troubleshoot or discuss new solutions.