-

MNU-2424 Ultrasonic Sensor

$624.95MNU-2424-C6-B81VIEW PRODUCTView ProductThe MNU-2424 ultrasonic level sensors provides a non-contact method of detecting level, presence/absence, volume, proximity and distance. Contact sales to discuss additional configuration options. 25 Feet Range

2 inch NPT

Modbus RS-485

6′ Cable (call for custom lengths)

[frequentlyBought ids="7621,6252,34491,7785"]

-

MNU-3434 Ultrasonic Sensor

$859.95MNU-3434-C6-B81VIEW PRODUCTView ProductThe MNU ultrasonic series provides a non-contact method of detecting level, presence/absence detection, volume, proximity and distance. Please contact our sales department for additional configuration options. 40 Feet Range

3 inch NPT

Modbus RS-485

6′ Cable (call for custom lengths)

[frequentlyBought ids="7621,6252,34491,7785"]

-

IRU-2423 Ultrasonic Sensor

$739.95IRU-2423-C6-B81VIEW PRODUCTView ProductThe IRU-2423 ultrasonic sensor provides a non-contact method of detecting level, presence/absence detection, volume, proximity and distance. Please contact our sales department for additional configuration options. 25 Feet Range – 2 inch NPT

4-20mA

6′ Cable (call for custom lengths)

Requires RST-3002 for setup.

[frequentlyBought ids="33924,6955,6938,8686"]

-

IRU-3433 Ultrasonic Sensor

$889.95IRU-3433-C6-B81VIEW PRODUCTView ProductThe IRU ultrasonic series provides a non-contact method of detecting level, presence/absence detection, volume, proximity and distance. Please contact our sales department for additional configuration options. 50 Feet Range – 3 inch NPT

4-20mA

6′ Cable (call for custom lengths)

Requires RST-3002 for setup.

[frequentlyBought ids="33924,6955,6938,8686"]

-

IRU-5413 Ultrasonic Sensor

$879.95IRU-5413-C6-B81VIEW PRODUCTView ProductThe IRU-5413 ultrasonic sensor provides a non-contact method of detecting level, presence/absence detection, volume, proximity and distance. Please contact our sales department for additional configuration options. 4-79 inch Range – 1 inch NPT

4-20mA

6′ Cable (call for custom lengths)

Requires RST-3002 for setup.

[frequentlyBought ids="33924,6955,6938,8686"]

-

MPX Float Sensor

$1,250.00MPXVIEW PRODUCTAdd to cartMonitor liquid levels with a float level sensor and a ControlByWeb® module. Receive text/email alerts when a user-specified level is reached. Log and graph a tank’s level data over time. Max Length: Up to 32ft. (175.25m)

Modbus RS-485

4-20mA, 2-Wire

External Power: 12-24 VDC

[frequentlyBought ids="7621,6252,33924,34491"]

-

PT-500 Pressure Sensor

$699.95PT-500VIEW PRODUCTAdd to cartMonitor liquid levels with a Pressure Transducer and a ControlByWeb® module Receive text messages or email alerts when a user-specified level is reached. Log and plot the level history, and more. Max Water Depth: Up to 575 ft.

Pressure Range: Up to 250 psig

Modbus RS-485 | 4-20mA

External Power: 10-28 VDC

[frequentlyBought ids="7621,6252,33924,34491"]

-

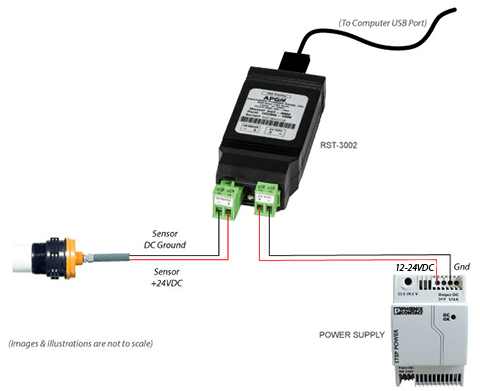

RST-3002 Ultrasonic Sensor Programmer

$119.95RST-3002VIEW PRODUCTView ProductThe RST-3002 Ultrasonic Sensor Programmer is used to program IRU Ultrasonic Sensors. The module connects your sensor to a computer with the IRU programming software installed. Programs all IRU Sensors

Includes USB Cable and Software

Connects to IRU-3433, IRU-2423, & IRU-5413

[frequentlyBought ids="7916,7924,7931,33924"]

Compatible Products

-

X-412™ | 4‐Channel Relay & Analog Input Module

$369.99 – $399.99X-412-I,X-412-EVIEW PRODUCTView ProductThe X-412™ is a powerful analog-to-digital Ethernet I/O PLC. It features 4 analog inputs, 4 relays, up to 16 1-wire sensors, and a built-in web server for infinite control and monitoring possibilities. - 4 Relays

- 4 Analog Inputs

[frequentlyBought ids="7624,7916,34491,7781"]

-

X-404™ | Modbus RS-485 Module

$399.99 – $499.99X-404-I,X-404C-I-CAVIEW PRODUCTView ProductThe X-404™ is purpose-built to monitor up to 32 Modbus RS-485 devices and/or sensors. It also includes a 1-wire bus for temperature and humidity monitoring. Modbus RS-485 input

Up to 16 temperature sensors

Cellular version available

[frequentlyBought ids="7624,7927,34491,7793"]

-

X-418™ | 8-Channel Analog Input Module

$369.99 – $399.99X-418-E,X-418-IVIEW PRODUCTView ProductThe X-418™ is a web-enabled analog module with eight configurable analog-to-digital inputs. Perfect for sensor monitoring for tank/bin level, pressure, flow, current, and more. 8 Analog Inputs (multi-function)

±1.28V, ±2.56V, ±5.12V, ±10.24V

4-20mA (Inputs 1-4 only)

[frequentlyBought ids="7621,34491,7916,7781"]

-

X-420™ | Instrumentation-Grade Data Acquisition

$369.99 – $399.99X-420-E,X-420-IVIEW PRODUCTView ProductThe X-420™ features software-programmable digital I/O that can be assigned as an input or an output. 4 Analog Inputs

2 Digital I/O

Up to 16 Temperature Sensors

[frequentlyBought ids="7621,34491,7916,7781"]

-

24V DIN Rail Power Supply

$74.992902992VIEW PRODUCTView ProductThe UNO POWER power supply unit impresses in worldwide use thanks to maximum energy efficiency. Low idling losses and the high degree of efficiency save energy. Thanks to its high power density, the UNO POWER power supply unit is the ideal solution, particularly in compact control boxes. Output: 24 V DC±1%, 1.75 Amp

Input Voltage: 100-240V AC

Input Frequency: 45-65 Hz

-

Power Supply | 12VDC

$19.99PS12VW1.5-NAVIEW PRODUCTView ProductRegulated

12V DC

1.5Amp (100-240V AC Input)

-

LPD Loop Powered Display

$254.95LPD-000001-C6-0-0-B81VIEW PRODUCTView ProductThe LPD Loop Powered Display is a user-friendly display compatible with select ControlByWeb devices. It is designed to be inserted into a 4-20 mA sensor current loop to provide a local display without additional wiring. Setup is easy using the 3 buttons on the display. Large, full 5-digit display with 0.4 in.

4-20 mA input

Easy 3-button programming

User-selectable units of measure

[frequentlyBought ids="33924,6955,7916,7924"]

-

MND Modbus Display

$503.31MND-202201-2-0-2-0000-B81VIEW PRODUCTView ProductThis user-friendly display is compatible with select ControlByWeb devices and does more than simply display its sensor’s readings. Features include the ability to alter sensor settings using the Modbus registry and to power a sensor with its batteries. Works on any Modbus network. Easy 3-button programming

RS-485: 9600 baud (Modbus RTU)

Local display for up to 10 sensors

Display: 5 digit LCD, 0.4 in. digits

[frequentlyBought ids="7927,7929,6252"]

Ultrasonic Level Sensors & Level Monitoring

Monitor liquid levels with an Ultrasonic Sensor and a ControlByWeb® module (See recommended products below) Receive text messages or email alerts when a user-specified level is reached. Log and plot the level history, and more.

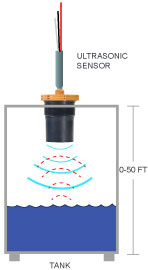

How Do Ultrasonic Level Sensors Work

Ultrasonic level sensors work by using ultrasonic waves to measure the distance from a target (i.e., a liquid surface). It measures distance by gauging the difference between the time the wave signal was sent, and the time the same wave was received after it bounced off of the surface.

For example, an ultrasonic water level sensor sends a signal that then bounces off of the liquid water level’s surface. This signal then returns back to the sensor which measures the round-trip time it takes for the signal to travel. The sensor uses the measured time to calculate the distance to the surface of the liquid. The sensor reports the distance to a display and/or a controller. Using this distance, along with the tank’s dimensions and volume, you can calculate how much liquid is left in the tank that you’re monitoring. ControlByWeb modules can calculate this information for you.

Features

- Monitor liquid levels

- Real-time level monitoring both locally and remotely

- Industrial-level monitoring for mobile and static locations

- Log level history

- Email/text notifications for high/low levels

- And much more…

Compatible Products

- Ultrasonic Sensor Programmer (RST-3002) For 4-20mA sensors only

- ControlByWeb Controller Module

- Power Supply

Liquid Types

Ultrasonic Level Sensor works well with many clean liquids; however, it is not ideal for foamy liquids, and chemicals that produce vapors, like gasoline.

These types of liquid can cause false readings when used with ultrasonic sensors.

Ultrasonic Sensor Benefits

- Easy to install.

- Provide a reliable, non-contact method for level monitoring!

Sensor Ranges

- We provide monitoring solutions for ranges from 4 inches to 50 feet.

Sensor Accuracy

- Sensors are accurate within 0.25% of its detected range.

Ultrasonic Sensors with ControlByWeb Products

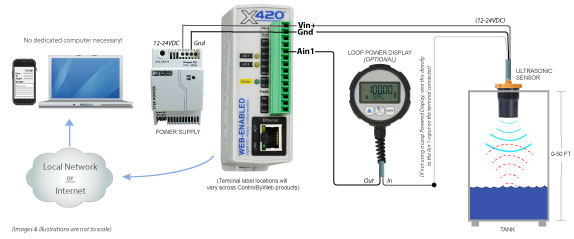

Real-Time Monitoring

Each ultrasonic level sensor can be connected to a compatible ControlByWeb module (see below) to remotely monitor liquid levels in real-time using a standard web browser or mobile device. Liquid levels can be presented to the user as a simple liquid height measurement, or the module can be configured to calculate the volume of liquid used or the volume remaining in the tank and present that to the user. No special software required.

Email and Text Alerts

When an ultrasonic sensor is connected to a ControlByWeb module, it can be configured to alert you via email or text whenever certain levels are reached.

Logging and Graphing

Log and graph tank and level data. Email log files at regular intervals.

Control Options

In addition to simple remote monitoring, ControlByWeb modules are fully programmable and provide custom control capabilities as well. For example, you can connect a pump to a relay or an output on a ControlByWeb module and remotely run the pump manually, or configure module to run the pump to run automatically if the level gets too low.

Ultrasonic Sensor connected to the X-420 to monitor tank levels. All products in this diagram can be purchased below.

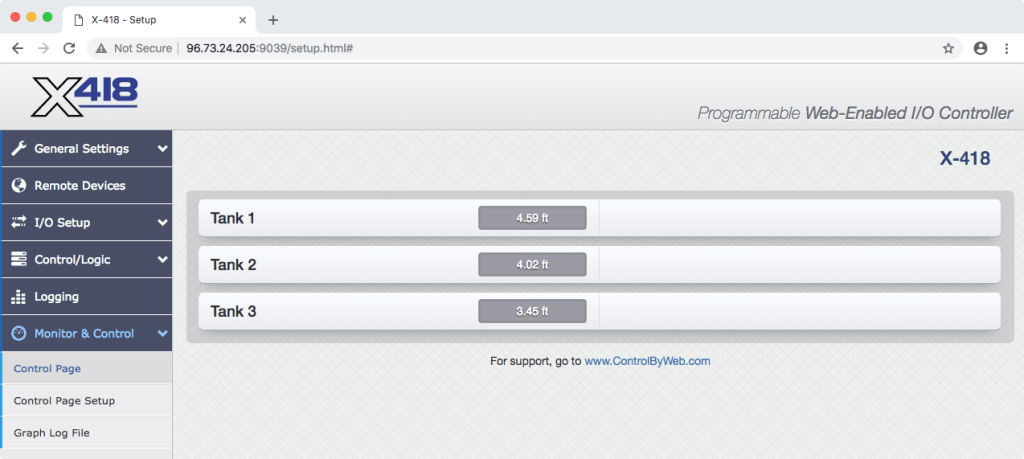

View live tank levels with ControlByWeb’s product’s built-in interface using a standard web browser

Common Level Monitoring Industries

Ultrasonic sensors are commonly used in the following industries:

- Medical Facilities

- Agricultural

- Waste Water Management

Programming the Ultrasonic Sensor using the RST-3002

Ultrasonic Sensor Setup

Connect Ultrasonic Sensor to the RST-3002 programming module, and adjust the parameters to suit your needs.

Disconnect Sensor from the RST-3002 and connect to a ControlByWeb product such as the X-418 or the X-420.

Connect the ControlByWeb product to your network. See Establishing Communications with ControlByWeb Products

Install Ultrasonic Sensor into the top of the tank.

Monitor your tank level from the internet anywhere in the world!