No-Code PLCs for Edge and IIoT Applications

Capture and use data at the edge with no-code, programmable logic controllers that feature embedded logic, data logging, and cloud compatibility. A built-in web server and intuitive drop-down interface simplify setup and support email notifications, advanced security settings, P2P communication, and multiple protocols. On-board logic is programmed using drop-down menus through “if this, then that” style conditions—no code required.

ControlByWeb PLC Devices

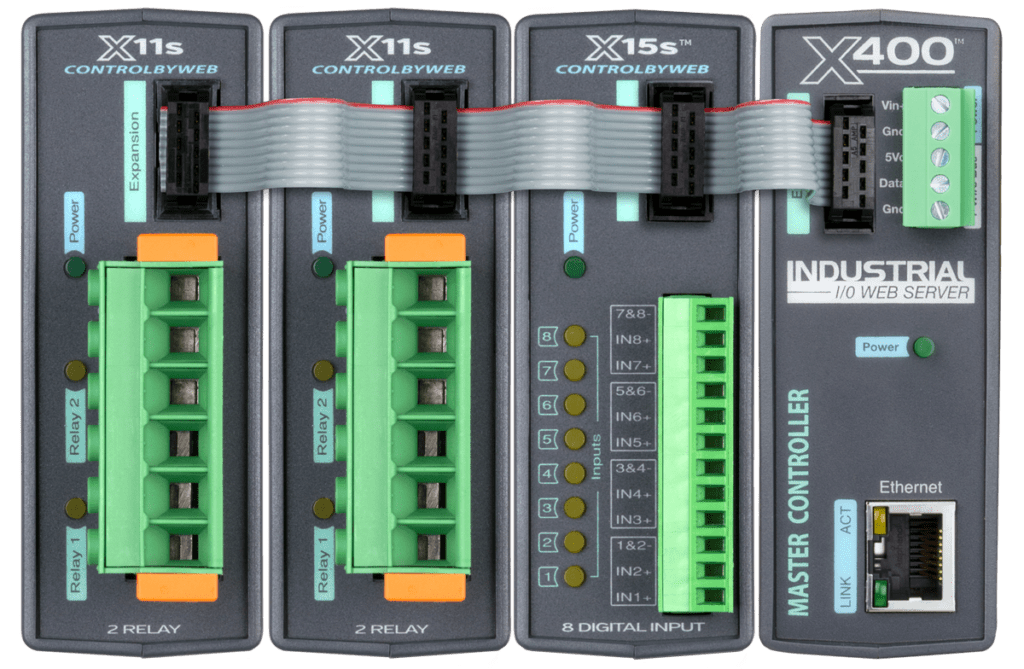

Modular PLCs

X-600M™

X-400™ & X-400C™

Standalone PLCs

-

X-410™ | Edge Programmable Controller

$299.99 – $329.99X-410-I,X-410-EVIEW PRODUCTView Product[product-icons ids="warranty_icon,cloud_icon,lua_icon,monkey_wrench_icon"]Simplify any industrial application with the X-410™—no code necessary. Automation is easy with its web-based interface, intuitive drop-down menus, and logic editor. Integrate different devices, sensors, and protocols to create a cohesive system that responds intelligently to changing conditions. Control lights, sensors, and more with built-in I/O and expandable modules. 4 Relays

4 Digital Inputs

Up to 16 Temp Sensors

WiFi is Now Available. Note that X-410W models include WiFi capability which allows for more flexibility and cost savings for your application. [frequentlyBought ids="7624,34491,7540,7798"]

-

X-401™ | Dual Relay and Input Module

$269.99 – $299.99X-401-I,X-401-EVIEW PRODUCTView ProductThe X-401™ has two SDPT relays (form C) and two optically isolated inputs. It also shares the same benefits as other 400 series devices, which includes a built-in web server and simple, no-code logic builder. Monitor locks and lights, reboot devices like IP cameras, control bells and alarms, and much more with the X-401. 2 Relays

2 Digital Inputs

[frequentlyBought ids="7624,7621,7798,34091"]

-

X-412™ | 4‐Channel Relay & Analog Input Module

$369.99 – $399.99X-412-I,X-412-EVIEW PRODUCTView ProductThe X-412™ is a powerful analog-to-digital Ethernet I/O PLC. It features 4 analog inputs, 4 relays, up to 16 1-wire sensors, and a built-in web server for infinite control and monitoring possibilities. - 4 Relays

- 4 Analog Inputs

[frequentlyBought ids="7624,7916,34491,7781"]

-

X-432™ | Advanced I/O Controller

$629.99X-432-IVIEW PRODUCTView ProductThe X-432™ is a standalone programmable PLC with 38 onboard I/O and support for local or remote monitoring and control task. - 16 Relays

- 18 Digital Inputs

- 4 Analog Inputs

- Up to 16 Temperature Sensors

[frequentlyBought ids="7621,34491,7540,7798"]

The Perfect Edge PLC

The Industrial Internet of Things (IIoT) has made monitoring and control at the Edge possible and cost-effective. But remote access is not the only criteria for the right Edge PLC. Here are the features needed to make the perfect programmable logic controller for the Edge.

On-board Logic

Logic is stored on the device to improve reliability regardless of network connectivity.

Optional Cloud Compatibility

Cloud services can improve data access and enhances system integration. Our devices are compatible with the ControlByWeb Cloud and third-party services.

Remote Notifications

Edge applications are often in remote places. Even when they’re not, notifying key personnel of important conditions is critical. Our PLCs include email notifications so important updates are made in near real time.

Easy Integration

Multiple protocols are necessary to be compatible with various control systems. We support MQTT, Modbus TCP/IP, HTTP, JSON, XML, and SNMP.

Flexible Application

ControlByWeb PLCs are built for flexibility. Most PLCs can be used in various applications, but we add flexibility in two important ways: ease of use and cost to own. This makes our PLCs a better fit for more applications—especially where speed and cost of programming, cost to deploy and maintain, and technical fit all need to be carefully considered.

Integration Ready

A big part of the genesis of our brand, ControlByWeb, was the ability to integrate with other systems efficiently. We looked forward then, just as we do now. Our devices use a variety of industrial and IT protocols including MQTT, Modbus TCP/IP, and SNMP. We also communicate using the very flexible and ubiquitous Hypertext Transfer Protocol, or HTTP. ControlByWeb PLCs include an embedded web server, so software developers can very easily poll our devices, set relay states, change register values, and more through a simple Get request.

How To Program Our No-Code PLC

Programming a PLC is typically a specialized task requiring a skilled engineer who isn’t always available. Even so-called “easy-to-use” PLCs on the market require Ladder Logic, Function Block, or some kind of diagram building with complex code, scripts, and a mountain of settings. On top of all that, most PLC user interfaces are overloaded with options, menus, sub-menus, wizards, modals, etc.

Our no-code PLCs use a very simple user interface with an uncomplicated, single menu system on the left-hand side. Most users will simply start at the top section and fill in the fields as they move down.

Programming logic is one of the simplest tasks for our users. Choose between scheduled or conditional tasks and use drop-down menus to select prebuilt options. These options are very straightforward, including turning relays on and off, sending email alerts, or logging a change under specific conditions.

Learn more about programming ControlByWeb PLCs.