A definition disclaimer: Like so much electronic terminology, “dry contact” has several synonyms and can have varying definitions and applications. Let’s break it down to its simplest form. By the end of this article, you’ll have a sense of why this distinction is useful, and why it’s true that you can use ControlByWeb relays to monitor any dry contact.

But First: Why Dry?

So, why are dry contacts considered “dry” in the first place? Because they’re not wet. (We know that doesn’t clear things up at all—keep reading!)

For years, electricity has been explained using water as an analogy of how electricity flows. It’s a natural comparison:

“The water/hose analogy for electricity is useful for explaining voltage, current, and power. In general terms, charge is water, voltage is the pressure of water, current is the flow of the water. Power is the total amount of water flowing in given time.” ‐ University of Washington’s Clean Energy Institute, Water Model of Electricity The analogy between water flow and electric flow helps explain the basic principles of electricity.

The Simple Definition

A dry contact is a contact that is isolated from a power source.

This means that, once a power source is wired to a dry contact, it becomes “wetted” and is now able to send a signal to a controller. Think of the comparison between an electric current and the flow of water—when it courses through the dry contact, it becomes “wet.”

Keep in mind that a dry contact has to be wetted for it to work; however, you can still define it as a dry contact if the power source comes from an external supply.

All of this is important as it helps to describe how a contact is wired. A wet contact, like a generator that has an integrated power supply, is easier to wire. A dry contact is simpler in nature but requires a power source to be run to the contact, making it more complex overall. However, in the realm of industrial low-voltage wiring, both are relatively easy to make work. (And it’s even easier when you have expert insight from the ControlByWeb sales and support team.)

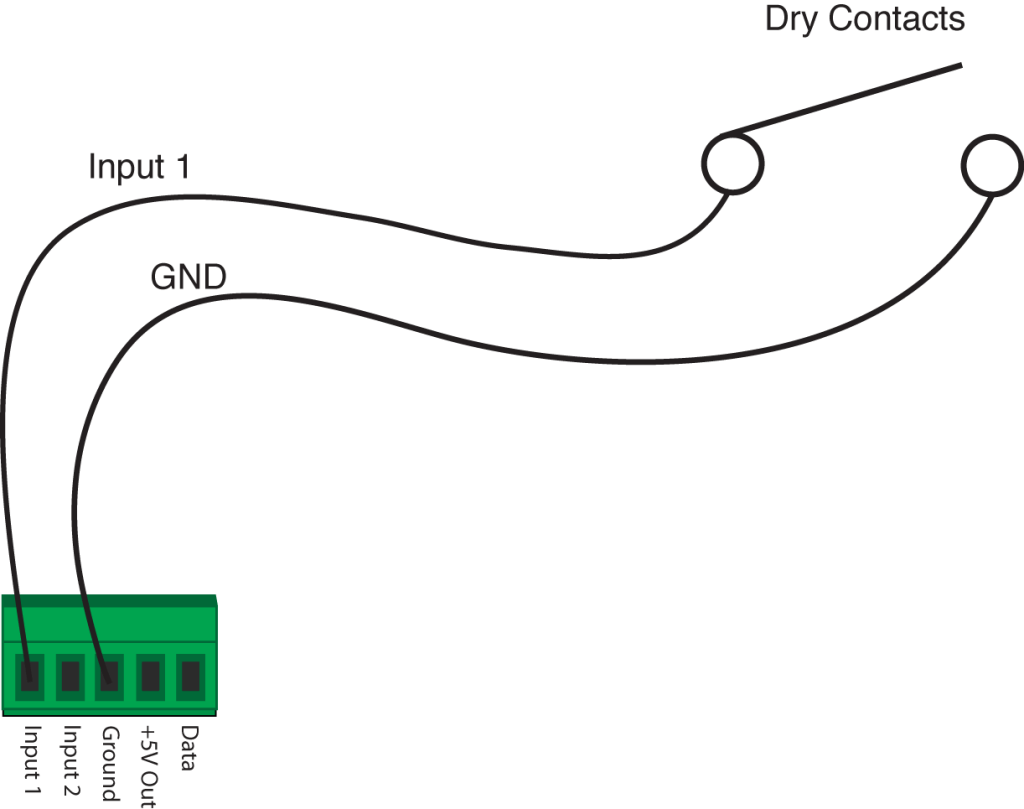

How Our Controllers Work With Dry Contacts

Nearly all ControlByWeb programmable controllers have digital inputs that can monitor dry contact switches. A low voltage is sent through the input to know whether a contact is open (incomplete circuit) or closed (completed circuit). Different actions can be taken based on either open or closed states.

Common applications where our customers would use dry contacts include buttons, door sensors, alarm panels, and float switches. In the case of alarm panels, our device acts as a supervised input to send an alert to specified users when the alarm changes state (when the alarm “goes off”).

Float switches in are another common use case for dry contacts. For example: A customer has a tank with a pump and needs to know when the liquid reaches a certain level to turn on the pump. Inside the tank, a dry contact is placed on a float, and the float switch is set to a certain liquid level threshold. When it triggers, our controller sends a command to turn the pump motor on. This command can be sent remotely to another location using peer-to-peer communication.

The ControlByWeb Difference

For help with your industrial application, get in touch with our team or schedule a 15-minute demo to get a feel for our devices.