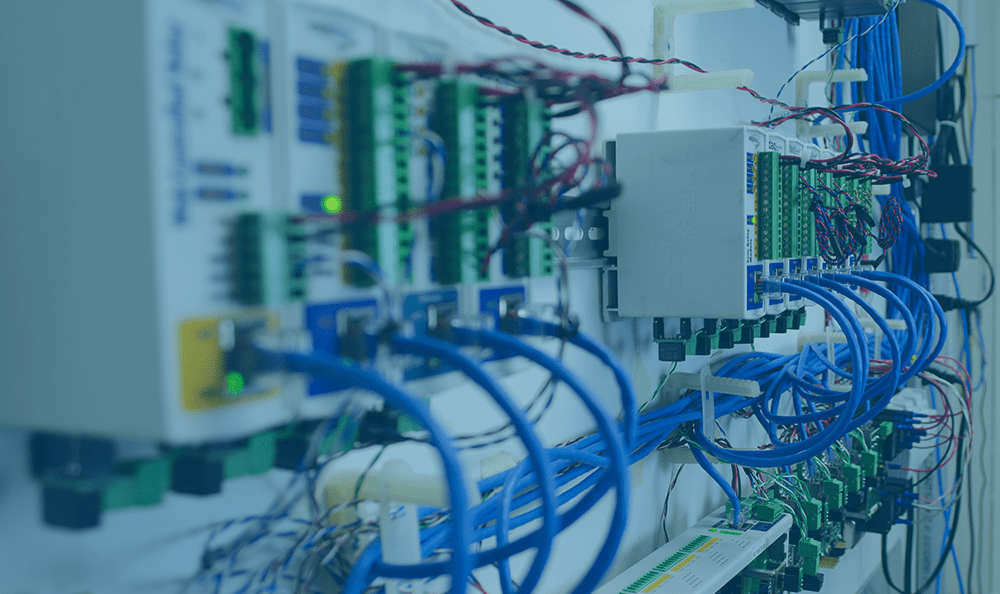

Factory assembly lines, ventilation systems, pumping stations—each of these industrial applications is powered by data. There’s a need to capture data frequently and share it across components, software, or personnel to keep things operating smoothly. A crucial component of modern industrial automation is the programmable logic controller, commonly referred to as a PLC.

In this blog post, we will delve into the world of PLCs, explaining what they are, how they work, and their significance in the realm of industry. We’ll also see how ControlByWeb PLCs stand out as prominent examples in the field.

What is a PLC Controller?

Programmable logic controllers have been around since the 1960s. They are sometimes referred to as “PLC controllers,” “controllers,” or “relays.” PLCs are used to control and automate industrial processes and machinery. Broadly speaking, a PLC is a specialized computer that reads signals from sensors and switches—inputs—and sends data or a command through an output. For example, the ControlByWeb X-410™ features four optically isolated digital inputs and four independently controlled low-voltage relays.

These controllers are designed to perform specific tasks, monitor inputs, and make decisions based on pre-programmed logic. At their core, PLCs are designed to operate in cycles, detecting the states of inputs and then determining how outputs should be affected. In this example using our X-412™ analog relay, a simple conditional task is created to control a tank pump. A liquid-level sensor feeds data back to the X-412, which will then determine whether the pump motor should be on or off based on the tank level.

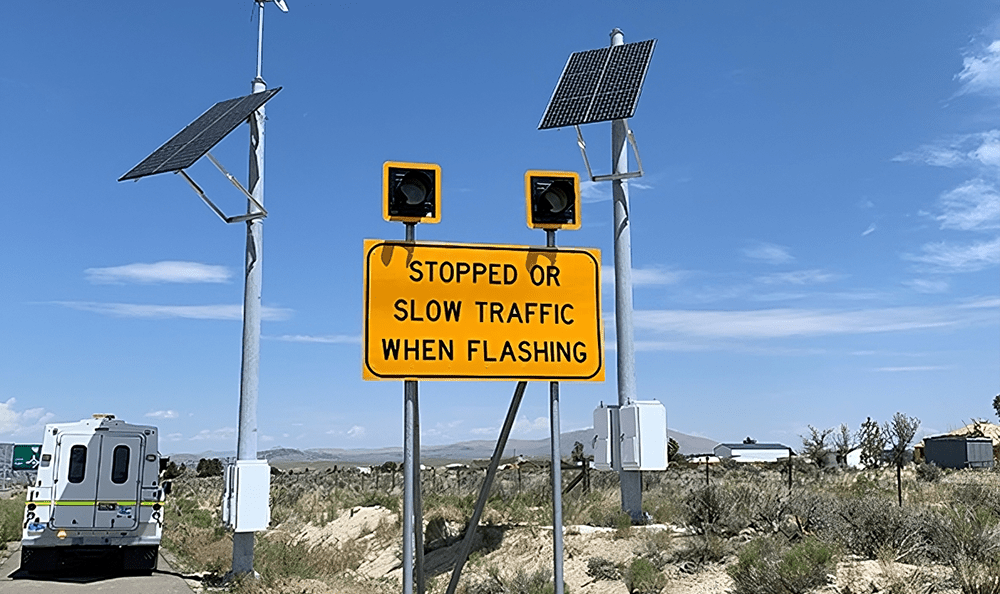

By automating tasks, PLCs minimize downtime and increase productivity. They also allow for redundancy in systems that are critical to maintain or physically remote. PLCs are found across numerous industries, including manufacturing, water/wastewater treatment, smart greenhouses, parking lots, and so much more. Visit our applications page to get an idea of the broad scope of applications where data makes a huge difference.

Components of a PLC Controller

A typical PLC controller consists of several key components:

- CPU (Central Processing Unit): The brain of the PLC, responsible for executing the program and making decisions.

- Input Modules: These modules connect to sensors and other input devices, allowing the PLC to gather data.

- The type of sensor a PLC can use is dependent on the input type as well as voltage. To ensure you’re using the right PLC for the job, contact our sales team.

- Output Modules: Output modules connect to actuators and devices, allowing the PLC to control machinery and processes.

- Memory: PLCs have both volatile (RAM) and non-volatile (ROM) memory for storing the program and data.

- Communication Ports: Some PLCs are equipped with ports for connecting to networks and other devices.

- Power Supply Input: PLCs will either accept power through a regulated power supply or Power Over Ethernet (PoE) switch.

Introducing ControlByWeb PLCs

ControlByWeb is a leading manufacturer of industrial automation and control solutions, including PLCs. Our PLC controllers are known for their reliability, versatility, and ease of use. Here are a few notable features that help our relays stand out:

- Web-Based Control: ControlByWeb PLCs can be accessed and configured remotely via a web browser. They are also compatible with the optional ControlByWeb Cloud.

- Wide Range of Inputs/Outputs: These PLCs offer a variety of input and output options, allowing them to adapt to various industrial applications.

- ControlByWeb relays are compatible with expansion modules and are also P2P-enabled, allowing for one device to act as a master to control, monitor, and log many additional I/O points—over 1,000 with the powerful X-600M™!

- Built-in Communication: ControlByWeb PLCs come with built-in Ethernet and cellular connectivity, simplifying integration into existing networks.

- User-Friendly Interface: The intuitive web-based interface makes it easy to program and monitor these PLC controllers.

- No-Code Logic: The intuitive web-based interface utilizes drop-down menus, making it easy for anyone to program scheduled and conditional tasks—no code necessary.

Driven by Data

In conclusion, a PLC controller, or programmable logic controller, is a crucial component in the world of industrial automation. These specialized computers perform a wide range of tasks, from process control to data handling, making them indispensable in various industries.

ControlByWeb PLCs stand out as a reliable and user-friendly option, offering web-based control and a wide range of features to meet diverse industrial needs.

As automation continues to shape the future of industries, understanding what a PLC controller is and its significance is essential for those looking to stay at the forefront of technological advancements. PLC controllers play a pivotal role in many industrial fields, optimizing processes and ensuring efficiency and precision.

The ControlByWeb Difference

For help with your industrial application, get in touch with our team or schedule a 15-minute demo to get a feel for our devices.